Belt Sizing

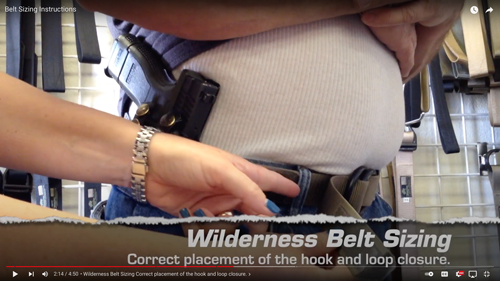

Video Guide: Wilderness Belt Sizing In Under A Minute

Video Guide: Extended Belt Sizing Directions

Our standard Original Instructor, LowPro EDC, and Frequent Flyer Belts are sized by a true measured belt size to the nearest single inch, not a two-inch range or generic small, medium, large, etc. Our Sport and Easy-Fit belts have more generous sizing, but we still strongly recommend checking your actual size. We ask that you put a cloth tape through the belt loops of the pants that you would normally wear the belt with, pulling as tightly as you typically pull a belt, and measure to the nearest single inch. If you regularly wear an in-the-waistband holster and mag pouches, we recommend you place them in your pants for measuring.

Ideally, the hook fastener material on the belt tab should center evenly in the loop fastener material area on the belt body. From an ideal fit you will then have 1-3/4" of adjustment in each direction. This is usually enough of an adjustment to cinch down for something heavy on the outside of the belt or loosen the belt for an in-the-waistband holster. If your I.W.B. holster is for a particularly thick gun, you may want to assume an extra inch.

Ideally, the hook fastener material on the belt tab should center evenly in the loop fastener material area on the belt body. From an ideal fit you will then have 1-3/4" of adjustment in each direction. This is usually enough of an adjustment to cinch down for something heavy on the outside of the belt or loosen the belt for an in-the-waistband holster. If your I.W.B. holster is for a particularly thick gun, you may want to assume an extra inch.

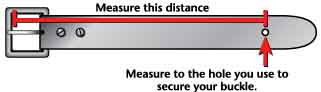

You can also measure by laying your leather belt out flat on a table, and measure from the inside edge of the buckle away from the hinge to the hole that you currently use. Measure to the nearest single inch as shown. It is important that the inside length of the buckle be included in the measurement. Please do not assume the size shown on your current belt is correct.

It is most common for a belt size to be 2"-3" larger than a pants size. This is because a pants size is a measurement of you, while a belt size is a measurement of you with a layer of fabric (your pants) wrapped around you.

If you would like any assistance in the measuring process, please feel free to call us. A quick call is easier and cheaper for everyone than a belt exchange.

Very Important: Proper Belt Use for Safety, Durability

Our belts are very tough but must be used properly according to the included directions. The operator MUST thread the belt tab properly through the buckle and around the floating bar (Instructor Belt) or between the rings (Frequent Flyer, Ring Belt) before fastening with the Velcro® (see pictures below). The hook-and-loop fastener is only to retain the loose end from flopping around; the buckles are designed to secure the belt. They will quickly lose their stitching and be destroyed if the buckle is improperly used. With proper threading, our belts should last for years. Of special importance, the Velcro® securing the end tab has no load-bearing capability on its own and the safety function of the Instructor Belts will be completely undermined if improperly used.

We recommend cleaning any lint or particles out of the hook and loop Velcro® once in a while to extend its life and maintain its adhesive abilities.

Belt FAQ

- Q: Will you make an Instructor-style buckle in plastic?

-

A: Absolutely not! We have gotten this request for many years, but we joke (well, half-joke) that we like our customers too much to kill them when explaining why we don't make plastic or cheap, un-rated cast aluminum versions. The Instructor Belt buckle design inherently encourages rappelling, rescue and securing usage because of its clip-in point, and we have no control of how a person may use that if it's there. We have never believed that either plastic or aluminum were adequate to safely support the dynamic loads associated with falls, and we believe it would be irresponsible of us to make this design in those materials. We also use a double-thickness of webbing and specific technical stitch patterns in the belt body because "probably good enough" just isn't when your life is hanging in the balance.

We designed our Frequent Flyer Belt for those who wanted a lighter weight, non-metallic sports or gunbelt with the same belt body as our Instructor Belt. Our Titanium Instructor Belt answers the need for a lightweight, corrosion-resistant, non-magnetic buckle that still passes the same lab tests as our Original Instructor Belt steel buckle. We would never use an inferior buckle any more than we would use an inferior, non-rescue grade stitch pattern or cheap nylon on a piece of equipment that could potentially be pressed into rescue service, even if the user had never foreseen the need.

These materials and manufacturing processes cost more, but we've never tried to be the cheapest, just the best.

- Q: I have a match this weekend, can my belt shipped today?

-

A: Maybe. We do keep a stock in our retail showroom, so if a belt in your size with your options happens to be there we can grab it and ship it to you immediately. However, our belts are still often made for specific customer's orders. Normal production is fairly quick, though; only 1-3 working days from the start of processing. Custom sizing may add to this as they require special attention. We do understand that events sometimes sneak up on us all, so we make a special effort to manufacture and get out expedited shipping orders as quickly as possible, often the same day. *Please remember that UPS does not count the day of shipment as part of a specific expedited service (i.e. 3-Day delivery is really the third day AFTER the shipping day, etc.). Weekend days are also not counted.

- Q: I've lost/gained weight...can my Instructor Belt be made shorter/longer?

-

A: Like most belts, the Instructor Belt™ has about a +1½"-1¾" range. This can compensate for normal shifts in weight and clothing, but not significant changes. The design and construction of the Instructor Belt does not lend itself to alteration due to the location of stitch patterns, the end-tab treatment, labor and shipping costs. However, if you email us to arrange to send us your old Instructor Belt buckle, we will be glad to give you a $17.00 credit and reuse it on your new belt (*The buckle is not refinished in recycling).

The customer pays shipping to us and $9.95 return shipping from refurbishment. - Q: When I put on my new belt there is still fuzzy Velcro® that shows past the end when I put it on. Did I get the wrong size?

-

A: Probably not. When sized and worn properly, the hook Velcro® on the tongue (the end of the belt) is supposed to be centered in the fuzzy Velcro® on the belt body, leaving an open area of fuzzy Velcro® on either side of where it mates. This is correct and allows about 1¾" of play either more tight or loose.

- Q: Does the end tab have to be tucked through my belt loops, or can it go over them?

-

A: The end of the belt does not need to go under your belt loops, but this is a judgment call by the user as long as the tab is retained. Even if the belt loop is between the mating Velcro® patches, there should still be ample contact area on either side for the fastener to do its job holding the tab in place.

- Q: Is there a right- or left-hand version of the belt?

-

A: No, actually our belts are ambidextrous and can be worn with the tab on the right or left-hand side. This is sometimes dictated by what equipment is on your belt and its position. Either way is correct.

- Q: I'm a big guy. Which stiffness option would be the most comfortable for me?

-

A: Surprisingly, our polymer-lined Combat Shooter's Model was originally designed specifically to offer more comfort and support to users with larger waist sizes. It turned out to be useful for a whole lot more, of course. We find most users in th 50"+ range prefer it.

- Q: Have you considered using Kevlar® in your belts' construction?

-

A: Kevlar® is still under consideration for the fire/rescue market where its heat-resistance would be useful. However, it may not offer enough increase in advantages to justify its current high cost of material and special production methods and equipment.

We believe that our current materials - the best we could get - meet the requirement, and its use by many fire and rescue personnel bear this out. Strength testing has shown they can take far more abuse than the human body could. As for heat and UV durability, we've had a pretty harsh testing ground here in Arizona, as well as professional users around the world. Like anything, even Instructor Belts have a service life, but it does seem to be pretty darned long with proper use. We chose not to use nylon thread in the belts because it is more susceptible to UV breakdown than the bonded polyester we use.

One of our hallmarks is that our products are never "done." We continually refine them and investigate new materials and designs. Our customers deserve that.

- Q: How much do the different buckles weigh?

-

A: These are the weights of our various buckles:

- Instructor Belt

- • Titanium: 2-3/8 oz.

- • Steel: 4-1/8 oz. (1½"), 4-5/8 oz. (1¾")

- Frequent Flyer Belt

- • Delrin: 5/8 oz. (1¼" or 1½")

- Ring Belt

- • Aluminum: 7/8 oz. (1¼)